Many companies round the globe are trying hard to make our lives smarter and a lot more quality oriented. Mobile phone companies like Motorola are also working out formulations and techniques, which would lead to a wide range of breakthroughs regarding cell phones. One of the prime things that concern a hell lot of cell phone users is the battery standby time and the battery life.

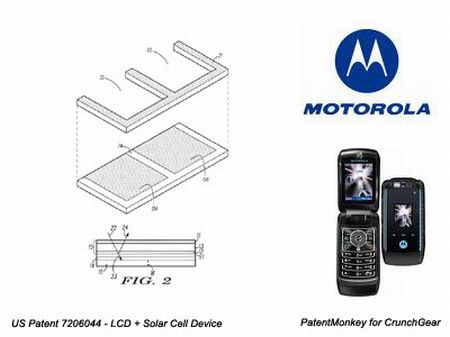

The innovators at Motorola have come up with a smart solution of combining a LCD screen and a solar cell on to a wireless device. It is said that the price tag it would carry would be a hefty one in comparison to the iPhone. Just like a solar cell, this technology incorporates light energy from any light source and converts it into electrical energy in order to drive the mobile phone. In this case, the LCD screen of the mobile acts likes a solar cell. Thus, it proves to be of dual functionality.

Motorola have made it quite clear that this technology is best only for the ‘Black’ LCD screens and accounts for a 75% accuracy and light translucency rate. ‘Wikipedia’ threw some light on this and opine that –

‘Many new solar cells use transparent thin films that are also conductors of electrical charge. The dominant conductive thin films used in research now are transparent conductive oxides (abbreviated ‘TCO’), and include fluorine-doped tin oxide (SnO2:F, or ‘FTO’), doped zinc oxide (e.g.: ZnO:Al), and indium tin oxide (abbreviated ‘ITO’). These conductive films are also used in the LCD industry for flat panel displays. The dual function of a TCO allows light to pass through a substrate window to the active light absorbing material beneath, and serves as an ohmic contact to transport photo generated charge carriers away from that light absorbing material. The present TCO materials are effective for research, but perhaps are not yet optimized for large-scale photovoltaic production. They require very special deposition conditions at high vacuum, they can sometimes suffer from poor mechanical strength, and most have poor transmittance in the infrared portion of the spectrum (e.g.: ITO thin films can also be used as infrared filters in airplane windows). These factors make large-scale manufacturing more costly’.

Seriously judging, this eco-friendly technology would certainly be of great use in the forthcoming years and would definitely contribute towards the new inventions and breakthroughs in this field.

Via: Crunchgear